Why COB package will gradually iterate over SMD package as a high-level panel manufacturing technology?

Table of Contents

LED display micro-pitch has become a trend in the development of the display industry. X, the role of SMD package, which occupies the mainstream position, is increasingly limited in the exploration of smaller pitch. In order to solve the problem of smaller pitch, alternative solutions such as “4-in-1”, “N-in-1” and COB technology have emerged in the industry.

COB encapsulation technology is the 1st generation of creation system technology without support integrated encapsulation system technology, while SMD encapsulation technology is proposed to belong to the 2nd generation of technology with support single device encapsulation system technology. These two technologies differ greatly in their ability to solve the pixel failure of LED display panels, and are the most real driving force for COB encapsulation technology to eventually replace SMD encapsulation technology.

Hundreds of LED enterprises in the fierce competition, the differentiation between small pitch products become more and more important. The competition of small pitch is first reflected in the technical level, SMD, IMD, COB packaging (front mount flip-flop) and other technical means of upgrading, Mini LED, Micro LED innovation and development, will improve the quality of LED products and application range. 2020 has more than 10 industry giants and listed companies to join the COB packaging technology industry, focusing on the investment of more than 10 billion yuan Industrial capital involved in COB small pitch display and Mini LED display field, so what exactly is the reason to promote the rapid development of COB packaging industry?

1.COB packaging technology

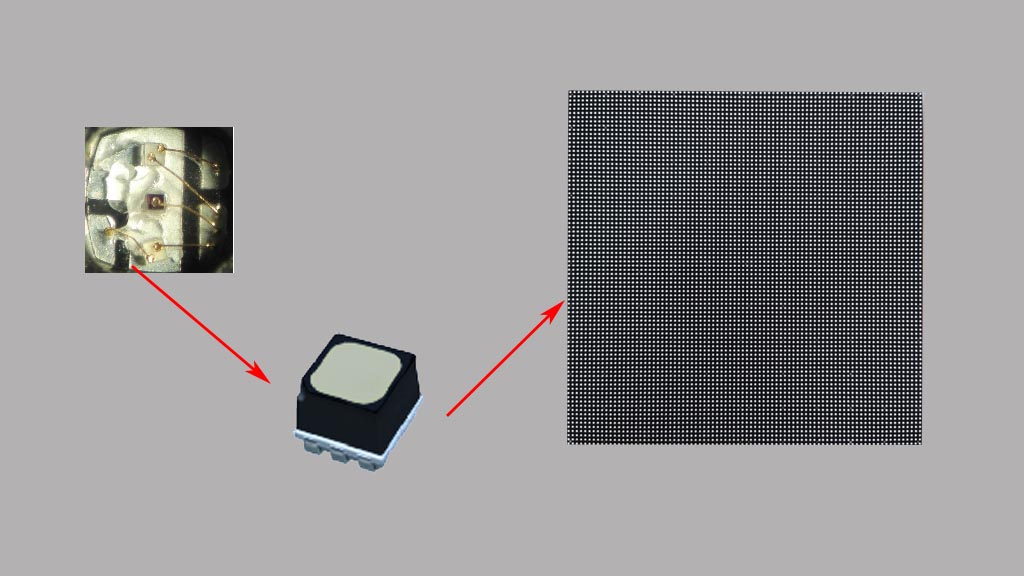

COB: It stands for Chip On Board. It means: chip on board packaging technology; that is, the chip is attached to the interconnected substrate with conductive or non-conductive adhesive, and then lead bonding to achieve its electrical connection of the semiconductor packaging process. Simply put, it is the light-emitting chip directly mounted on the PCB board, without the need for brackets and solder pins. Compared with the traditional SMD approach, COB package omits the LED chip into a lamp bead and reflow soldering two major processes. The chip is assembled directly onto the PCB basically, without the limitation of the package device size, which can achieve a smaller dot pitch arrangement, and the current Micro LEDs are using COB technology.

The process of COB technology is much simpler than other packaging technology, relatively simple, and the product features are as follows:

1. Super “stability”: almost trouble-free, no dead spots.

2. Not “blinding”: the use of surface light source rather than “blinding” point light source and other environmentally friendly technologies. The brightness is soft and protects the human eye.

3. Not “delicate”: not afraid of bumping, can be wiped with water, protection level IP66.

4. No “spell”: you can “private customize” the precision display of different scales.

5. Use “long life”: 24 hours 365 days continuous use of more than 8 years (theoretical 10 years).

6. “Is the future”: will replace DLP, LCD, plasma, projection, movie screen, SMD LED display and other display products.

2.SMD packaging technology

SMD: it is the abbreviation of Surface Mounted Devices, meaning: surface mount devices, it is one of SMT (Surface Mount Technology) components. At present, the indoor full-color LED screen mainly adopts surface-mounted three-in-one SMD, which refers to the packaging technology of RGB three different colors of LED chips encapsulated in SMT lights according to a certain spacing encapsulated in the same gel to form a display module.

The main process is to encapsulate the LED light-emitting chip in the holder to form a lamp bead (SMD surface mount), which is then attached to the PCB board through soldering. Then the SMD parts and PCB board are put into high temperature oven for sintering and solidification (reflow soldering), finally forming the display module, which is then assembled into a unit.

SMD production

SMD process of the core materials.

Bracket: conductive, support and heat dissipation, mostly for the bracket material after plating and formed, from the inside to the outside of the material, copper, nickel, copper, silver, which is composed of five layers.

LED chip: the chip is the main component of the LED Lamp materials, is the light-emitting semiconductor material.

Conductive wire: connects the wafer PAD (solder pad) and the holder, and enables it to conduct.

Epoxy resin: protects the internal structure of the lamp beads, and can slightly change the light-emitting color, brightness and angle of the lamp beads.

3.Million vs 10,000

The millions and tens of thousands mentioned here refer to the defining indicators of packaging technology in addressing the pixel failure capability of LED display panels. Research shows that

1. the COB package is the million-level technology, its pixel runaway rate indicator can be controlled within 1-9/PPM, meaning that 1 million display pixels will be within 1-9 pixel failure points. SMD package technology is the million-level technology, its pixel runaway rate indicator >100/PPM, meaning that a good state can only reach 10,000 pixels on one failure point. 30 years of industry practice More than 30 years of industry practice shows that the stent package technology is not capable of breaking through the 10,000 level, and generally will be in the range of 1-9/10,000. 2.

2. stent packaging technology pixel failure is divided into internal failure and external failure, the number of internal failure and external failure ratio is about 1:9, that is, SMD packaging technology pixel failure is mainly caused by external failure, external failure is the reason for the use of the package device stent and pin.

3. LED display industry needs to reflect, we are not to LCD LCD panel standards, to provide customers with millions of display panel products, rather than ten thousand products. Imagine a million and million level two choices to tell the end customer, even if the price of million level products are cheaper, customers will definitely choose a million level, because the gap is not a star and a half, but two orders of magnitude difference. This gap will be reflected in the customer can accept the high cost of maintenance and low-grade display effect. At present, the only technology that can provide million-grade products is the COB integrated package as the representative of the bracketless integrated packaging system technology, that is, COBIP (Chip On Board Integrated Packaging) technology.

4. Front mount chip and flip chip

After deciding the general direction of the choice of packaging technology, that is, after choosing the COBIP packaging technology, LED display panel products may have a million labels, front-mounted chip or flip chip?

Research shows that.

4.1. packaging technology is more important than chip technology

From the point of view of the ability to control the runaway pixel, we put forward such a view on several platforms in the industry, that packaging technology is more important than chip technology. Why say so can? Because LED chips have a problem of what packaging technology route to take, whether it is flip chip or front mount chip, if you choose the bracket packaging technology route, you can not jump out of the 10,000 capacity circle, the advantages of flip chip will not play out. On the contrary, if you choose the stentless integrated packaging technology route, the control panel level pixel runaway ability to start is already a million. For this reason, we have been saying that LED chip technology can only reflect the height of the industry’s technological development, but it can not influence the direction of the industry’s development, the industry’s development direction is never dominated by the packaging technology. If you agree with the goal of the million efforts, the conclusion is that packaging technology is more important than chip technology, that is, the choice of direction is more important than reflecting the height.

4.2. The role of COBIP package technology and flip chip technology

COBIP technology because it is a bracketless integrated packaging system technology, it solves the SMD bracket packaging technology by the bracket pins triggered by all the pixel outside the failure problem, that is, COBIP technology to solve the traditional SMD technology of the total pixel failure of about 90% of the problem, so the ability to reach a million is easy to understand.

And the role of the flip chip is used to solve the remaining 10% of the role of the internal failure problem, which can reduce the remaining 10% of the internal failure problem by another half.

So the flip chip + COBIP technology combination can reduce the total failure generated by SMD packaging technology by about 95%, this technology combination produces the LED display panel failure is only about 5% of the SMD technology. In other words, the flip chip + COBIP technology combination is the most cutting-edge technology in the LED display industry at present, and this technology is not only applied to small-pitch display and MINI LED technology, but also has strong advantages in all LED display panel applications.

4.3. Other advantages of flip chip

In addition to the above mentioned roles, flip chip also has the advantage of high luminous efficiency and high brightness, which is about two times higher than the front-mounted chip. This can provide a more energy-efficient and power-saving product solutions when too much brightness is not required, and also provides years of brightness decay compensation reserves, which is not possible with SMD packaging technology. If SMD package technology cannot provide brightness compensation, eventually the device will be replaced again due to insufficient brightness.

5.Iteration and Revolution

In the long run, in addition to the above-million advantages, COB package products also have the advantages of high reliability, small size, moisture-proof, anti-collision, high protection level, no glare, no exposed pins, ultra-thin, bendable, nearly 180 degrees large viewing angle, super anti-knock ability of the lamp beads, and other advantages, such as wide color gamut, large viewing angle, the lowest point spacing, and not afraid of humidity, salt fog, chemical rot environment. However, as a new technology applied in the small-pitch LED industry, COB also has relatively high cost, lack of consistency and inconvenient maintenance and other shortcomings, which is precisely the key to restrict the application of COB technology.

The more the development of micro-pitch direction, SMD by the physical limits and processes, etc., currently encountered three major reliability and stability problems: 1. package airtightness, poor protection, so more dead lights, caterpillars and other reliability problems; 2. bead pad welding area is small, handling, installation, bump in use is very easy to damage the beads; 3. bead pad exposed, dry environment, human touch screen generated by static electricity is very easy to Break through the lamp beads.

It is understood that in the field of conference all-in-one machine, COB compared to the traditional SMD packaging technology LED’s most prominent advantage is “handwritten”, to better realize the human-computer interaction function, this function can significantly enhance the customer’s meeting experience. In addition, due to the technical defects of SMD, it is difficult to mass-produce below 1.0mm pitch, and with the future consumer upgrade, the micro-pitch products below 1.0mm are expected to become the mainstream of the market, when the advantages of COB products will be more obvious.

6.Differentiation advantages of COB package products

Flip chip + COB package can gradually heat up, more than ten billion industrial capital striving for it, Made in China is achieving the metamorphosis from low-end to high-end manufacturing, COB package behind the bracketless integrated packaging innovation system technology is to adapt to such a market hope, it is the real motive to promote this technology iteration. First of all, driven by the demonstration effect of COB small pitch and Mini LED in flip-chip COB, it will produce a strong benchmark effect in the whole industry, and then let COBIP technology sink into more and wider application fields, such as vehicle mobile media advertising applications, glass curtain wall display applications, etc., and finally realize the revolution of the whole industry chain.

As the supply capacity of COB technology-based small-pitch LED display products improves, market awareness and acceptance also continue to increase. As one of the technical routes of small-pitch LED products, the emergence of COB technology intensifies the competition within the industry, which is beneficial to the whole industry to maintain a healthy development trend and provide sufficient technical reserves for the future market. At the same time, COB technology, as a differentiation weapon for “latecomer” brands in the small-pitch LED industry, will focus on improving the visual comfort of products and further enhance the competitiveness of small-pitch products to replace other large-screen splicing screens.

LED small pitch display is a high growth market, the current COB technology in the field of LED small pitch is a technology leader, less competition, is the industry blue ocean; large size commercial display, COB can bring greater value for commercial display; ultra-high-definition, based on the flip COB micro led in the breakthrough to higher resolution. The advanced technology of LED small pitch.

COB micro display products display effect is outstanding, far beyond the ordinary traditional LED to bring the presentation effect of goods. In addition to the analysis of major industry organizations, it can also be seen from industry exhibitions that 0.6-0.9 pitch LED products have entered a highly mature stage, while most of these products are based on COB technology. Overall, COB small pitch is getting smaller and smaller, and the market demand for display based on COB technology is strong, and the scale benefit is continuously released. It is not difficult to find that COB technology small pitch has entered a period of rapid development, whether in the breakthrough of point pitch or market applications. Analysis from the industry, the post-epidemic era, LED display applications will be enhanced, telemedicine, mass transit, teleconferencing systems and other niche application markets.

At the same time, LED small pitch based on COB display technology will become the mainstream of high-definition display within three years, and gradually penetrate into commercial display and civil display, gaining greater market space (more than $7 billion). Industry insiders predict that from 2021, the COB market will grow at an annual rate of more than 50%, and in 2023, COB will become a billion-dollar market.

Subscribe

Join us to learn the latest technology together